SKU complexity is rising faster than many operations can adjust. Seasonal promotions, sustainability requirements, and ever-changing packaging formats make it difficult to keep production lines stable and cost-efficient. Without a line built for flexibility, manufacturers risk downtime, expensive retooling, and slower speed to market.

A future-proof packaging line reduces those risks. By combining modular packaging equipment, scalable packaging solutions, and advanced packaging automation, SKU variability can be managed while preparing for what’s next. The right investment ensures agility, cost control, and consistency even as product portfolios expand.

1. Assess Current SKUs and Anticipate Change

The first step is taking stock of what you produce today and how it could evolve. SKU growth often accelerates in response to consumer demand, sustainability initiatives, or retailer requirements. Without preparation, each variation, whether a new size, eco-friendly material, or limited-edition run, can slow production or require costly modifications.

The first step is a structured assessment of SKU variability to identify where complexity creates the greatest operational strain.

- Dimensions and Weights: Identify the full range, including potential future formats.

- Packaging Materials: Plan for current substrates and emerging options such as recyclable film or lightweight cartons.

- Labeling Requirements: Consider compliance-driven changes and marketing updates that may affect line configuration.

Forecasting future needs should involve multiple teams. While sales and marketing can anticipate promotional cycles, R&D could introduce new materials, and regulatory teams can track labeling requirements. By taking a cross-functional approach, manufacturers reduce the risk of reactive spending and create space for sustainable growth instead of costly constraints.

2. Choose Configurable, Scalable Machinery

Equipment that cannot evolve becomes a bottleneck. Fixed-capability machines may meet current needs, but once SKUs shift, changeovers can become slow and costly. To protect return on investment (ROI), machinery should be both configurable at installation and flexible for future expansion.

Advantages of scalable packaging solutions include:

- Reduced Downtime: Operators can switch formats in minutes instead of hours.

- Scalable Expansion: New modules can be added to increase line speed or accommodate more SKUs.

- Extended Equipment Lifecycle: Machines remain valuable longer, reducing the risk of premature replacement.

Modular designs allow manufacturers to reconfigure or expand capacity over time, without replacing the core system. This lowers long-term costs and supports incremental investment as product lines grow.

3. Automate With Smart Controls and Connectivity

Smart controls and digital connectivity provide the visibility and responsiveness needed for evolving product mixes.

Connected systems across packaging stages offer real-time data on performance, bottlenecks, and maintenance requirements, allowing manufacturers to:

- Track Production Metrics: Monitor throughput, changeover speed, and error rates

- Enable Remote Diagnostics: Reduce downtime with faster issue resolution

- Optimize Changeovers: Adjust parameters digitally without lengthy manual intervention

- Receive Software Updates: Extend functionality without replacing hardware

These capabilities future-proof packaging lines by ensuring they can adapt not only physically but also digitally. As new SKUs demand different handling, controls can be updated to match, keeping performance consistent.

4. Build an End-to-End, Modular Solution

Future-proofing is most effective when every stage of packaging is designed to work together. Fragmented setups often create bottlenecks and inefficiencies during SKU transitions, while modular, integrated equipment allows the entire line to adapt seamlessly from one run to the next.

- Consistent Quality: Uniform handling across all SKUs reduces variation.

- Simplified Maintenance: Fewer isolated systems mean less downtime.

- Reduced Total Cost of Ownership: Upgrades can be applied to parts of the system without full replacement.

- Flexibility Across Runs: Handle both high-volume production and short custom batches.

This approach also strengthens data tracking across the line, supporting compliance reporting and quality assurance. By designing with modularity in mind, manufacturers improve efficiency and create a system that evolves alongside their product mix.

5. Plan for Sustainability and Compliance

Sustainability is one of the strongest drivers of SKU evolution. Governments are tightening packaging regulations, retailers are pushing for recyclable formats, and consumers expect brands to reduce their environmental footprint. These combined pressures often require changes to materials and formats at short notice.

Recent mandates, such as the EU’s single-use plastics directive and extended producer responsibility programs in North America, are accelerating the adoption of lightweighting, recycled substrates, and mono-material packaging. Production lines built only for conventional cartons or films can quickly become obsolete as these requirements take hold.

Future-proof packaging lines support sustainability by:

- Running Recyclable Substrates: From PET shrink film with recycled content to corrugated cartons with reduced fiber.

- Accommodating Lightweighting: Machines designed with adaptable tension and sealing controls can manage thinner materials without breakage.

- Supporting Labeling Updates: Smart controls make it easier to apply compliance-driven changes in language, barcoding, or QR-based traceability.

For example, beverage producers who once relied on heavy glass have shifted toward lighter PET bottles and recyclable trays. Modular packaging equipment allows them to adapt quickly, ensuring that regulatory compliance and brand commitments do not disrupt throughput.

Manufacturers that design with these realities in mind not only avoid penalties and supply chain setbacks but also demonstrate alignment with customer and market expectations.

Protecting ROI With Technology and Service

Every minute of downtime in a high-speed packaging line represents lost revenue. If an average line produces 300 units per minute, a one-hour changeover equates to 18,000 missed units. At a conservative $1 margin per unit, that’s an $18,000 opportunity cost for every lengthy adjustment. Multiply that across multiple SKU transitions each week, and the financial impact is substantial.

Fixed vs Modular Equipment

Modular equipment provides a stronger foundation for future-proof packaging lines. Instead of costly retooling, manufacturers can expand incrementally, aligning investments with growth.

By contrast, modular systems designed for rapid changeovers can reduce setup time from hours to minutes. For example:

- Traditional Changeover: 90 minutes to adjust for a new SKU, resulting in 27,000 lost units at 300 units/minute.

- Modular System Changeover: 15 minutes, losing only 4,500 units.

The net savings per changeover are 22,500 units, or $22,500 in margin preserved. These are not abstract numbers; they represent measurable ROI. For manufacturers running weekly SKU changes, the difference between outdated equipment and scalable solutions can translate into millions of dollars saved each year.

| Factor | Fixed Equipment | Modular Equipment |

| Changeover Speed | Hours of downtime | Minutes with digital or mechanical adjustments |

| Scalability | Requires full replacement | Add modules as demand grows |

| Cost Over Lifecycle | Higher due to frequent replacements | Lower with extended equipment lifespan |

| Adaptability |

Limited to current SKU formats |

Configurable for new sizes, weights, and materials |

Lean on Support That Keeps You Running

Safeguarding ROI, however, requires more than technology. Even the most advanced packaging equipment requires support to operate at peak performance.

- Service agreements and preventive maintenance programs protect uptime and extend system lifespan.

- Access to responsive technical assistance and readily available spare parts ensures that production can continue with minimal disruption.

This financial protection extends beyond throughput. By avoiding early replacement of fixed-capability equipment, manufacturers extend the life of their capital assets. Meanwhile, service agreements and preventive maintenance ensure consistent performance, reducing emergency repair costs and maximizing the return on every dollar invested.

Partnering with a provider that prioritizes long-term service and flexible packaging automation allows manufacturers to protect both their investment and their production schedules.

Position Your Packaging Line for What’s Next With OCME

Adapting to evolving SKUs requires more than quick fixes. It demands packaging automation that is scalable, configurable, and supported by a long-term partner. Manufacturers that plan for change can protect efficiency, avoid downtime, and maintain consistent product quality.

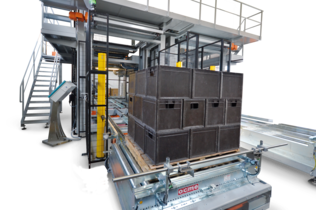

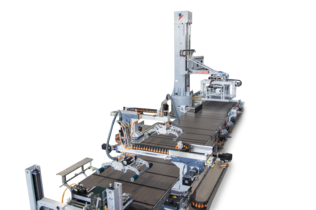

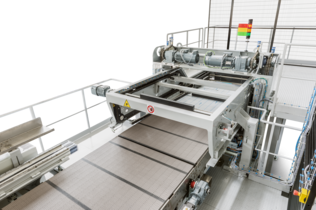

OCME’s packaging system and modular solutions provide the tools to achieve this:

- Delivers end-to-end packaging automation USA manufacturers can rely on, covering filling, case packing, palletizing, wrapping, and automated material handling with AGVs and LGVs.

- Modular systems with an integrated approach allow each stage to expand or adjust as requirements change.

- OCME’s product range and systems support rapid changeovers across varied formats, from small retail packs to bulk distribution sizes.

- 24/7 technical assistance, spare parts supply, and operator training ensure that adjustments for new SKUs can be made quickly, without extended disruption.

OCME demonstrates its approach through industry events and real-world projects.

At ProMat 2025 in Chicago, Aetna Group highlighted how modular and connected technologies can help manufacturers prepare for SKU complexity. OCME showcased systems designed for flexibility, safety, efficiency, sustainability, and improving internal logistics, core attributes of a future-proof packaging line.

Another strong example is OCME’s work with CEPSA, where modular systems allowed production requirements to evolve without disrupting throughput, proving the long-term ROI of scalable design.

If you are evaluating how to safeguard your operation against SKU complexity, OCME USA can help you design a solution tailored to your production goals. Contact us today to learn how we can help you future-proof your packaging line with modular, scalable solutions that keep pace with evolving SKUs.