On this subject, Andrea Regis, plant director of the Quarona plant, says: “The main benefits we have obtained from this investment include: improved line efficiency; a reduction in stoppages; and a reduction in bottle collisions that will enable us to give our consumers an even better product. We chose OCME as our partner because we have been working with OCME for several years in many plants and they have consistently been able to provide us with customised solutions tailor-made to our high-tech and state-of-the-art requirements.”

OCME's Leo has also been introduced at the Recoaro plant in Vicenza. It was configured to handle dual-track crates with simultaneous input, to meet customer production requirements.

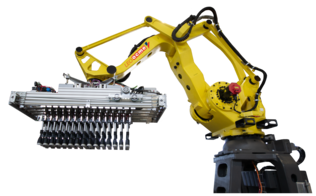

LEO craters and decraters are equipped with dedicated working heads, which operate alternately according to the formats to be processed. During format changes, the heads and crate centring devices are replaced, thereby ensuring greater precision when handling different types of formats.

Regarding after-sales services Andrea Regis adds:

“The after-sales services provided by OCME have been excellent, especially regarding the installation of this new system, as the start-up was quick and efficient.

Even with some minor issues that arose during installation, we had a quick response followed by the prompt resolution of all the problems”.

At the end of the line, Robopac branded wrapping ensure effective pallet protection and stabilisation, Recoaro's main need for its products, due to some problems encountered with the previous technological solution. Robopac's Kratos, a fully automatic robotic wrapping machine, is the latest model presented by the Rimini-based company. It was chosen by Refresco, from among the wide range of automatic pallet wrappers, to wrap pallets of beverage products with stretch film, guaranteeing the integrity of the pallet during handling and transport with effective protection up to the point of sale.

The line consists of an independent pallet top cover system and the robotised wrapping station. The wrapping, thanks to Cube Technology™ with which the pre-stretch carriage is equipped and thanks to the extensive stability tests carried out in Techlab Robopac, is designed to deposit the exact amount of film, in a precise position and with a precise containing force. The combination of Robopac's patented technology and decades of experience gained from more than 6,000 stability tests conducted in the Robopac Technology Centre allow palletised loads to be stabilised while saving up to 50% in material when compared to conventional solutions, resulting in improved packaging quality and increased line performance.

The collaboration between Refresco and the Aetna Group has led to remarkable results in the optimisation of packaging and wrapping lines. The introduction of OCME and Robopac technology solutions has significantly improved operational efficiency, stabilised pallets, reduced bottle wear and optimised bottle reuse. These technological advances have not only simplified operations, but also contributed to a significant reduction in maintenance and operating costs. The synergy between the two companies is an example of how technological innovation can transform industrial operations and support continued growth in the beverage industry.