Throughput defines the productive capacity of your packaging operation, yet many manufacturing facilities operate well below their theoretical maximum without understanding why. The gap between expected performance and actual output often stems from throughput limits, i.e., bottlenecks and constraints that restrict flow through your system.

When you understand where these limits originate and how they interact, you can make strategic improvements that deliver measurable results. This insight is especially critical when evaluating investments in palletizing automation and other technologies that enhance packaging line efficiency.

What Is Throughput in Automated Packaging Systems?

Throughput is the rate at which your packaging line turns product into shippable output over time. At the end of the line, you typically express it as cases per minute or pallets per hour. This metric represents the actual productive output of your system under real operating conditions, not the theoretical maximum speed of individual components.

Because “speed” can mean different things depending on who you ask, it helps to define three distinct measures that show where performance is gained or lost:

- Rated speed is the maximum speed a machine can reach under ideal conditions.

- Sustainable speed is the speed you can maintain while meeting your quality requirements and changeover practices.

- Effective throughput is what you actually ship after downtime and short stops are counted.

If you care about packaging line efficiency, effective throughput is the metric that matters.

Common Throughput Limits and Where They Come From

Throughput limits rarely announce themselves clearly. They hide in cycle times, accumulate across transitions, and emerge from the interaction between components that each perform adequately in isolation.

Identifying these constraints requires looking beyond individual machine specifications to understand how your system behaves as an integrated whole.

- Station-Level Cycle Limit: Case packing, palletizing, wrapping, and label verification often cap the line. In palletizing automation, the limit is the full handling loop, including gripper actuation, placement settle time, and any required confirmation signals.

- Insufficient Buffering: Without enough accumulation in the right place, a short downstream pause forces upstream equipment to stop and restart. Restarts add losses through misfeeds, unstable spacing, and extra fault checks.

- Unstable Flow on Conveyors: If gaps and orientation drift, sensors mis-detect, transfers misalign, and robots miss picks. Light cases, variable case sizes, and changing friction make spacing control harder. The symptom may appear as a conveyor problem, but the result is lower output.

- Quality and Verification Steps: Print-and-apply labeling, barcode grading, checkweighing, and vision inspection add latency. If the line cannot accumulate ahead of these steps, small interruptions turn into full stops. Frequent rejects can also choke the reject path.

- SKU Mix and Changeovers: High product variety limits throughput through tooling adjustments, recipe changes, and pallet-pattern switches. Manufacturing throughput optimization often begins by measuring how much time you spend changing states rather than producing.

- Reliability and Recovery Time: A fast line with frequent faults will ship less than a slightly slower line that restarts quickly. Recovery time is a throughput variable you can design for.

- Upstream Variability: Case squareness, seal quality, count accuracy, and infeed consistency flow into end-of-line packaging automation. If upstream variation exceeds what the end-of-line can tolerate, your bottleneck may sit earlier than the palletizer.

How Throughput Limits Impact Your Operation

Throughput limits rarely remain confined to a single station. A small constraint at the end of the line can trigger stop-start behavior upstream, increase manual intervention, and push equipment outside its stable range. Over time, that turns a capacity issue into a recurring operational drain.

Here are other ways throughput limits impact your operation:

- They compress your capacity margin. When effective throughput trails demand, you rely on overtime, inventory buffers, or shipment prioritization.

- They change where labor goes. Automation can remove repetitive handling, but chronic stops shift labor toward intervention: jam clearing, manual pallet correction, and coordinated restarts.

- They increase quality exposure. Running beyond a station’s stable range can create misapplied labels, unstable loads, and case damage. Rework consumes time twice.

- They raise the maintenance load. Frequent start-stop cycles stress drives, pneumatic components, and grippers. In an automated palletizing system, repeated protective stops and recovery checks reduce available run time.

- They can raise safety risks. More manual interventions around conveyors, pallet loads, and forklift lanes increase exposure.

Strategies to Maximize Throughput

To maximize throughput, you get more leverage by reducing losses than by pushing top speed. Here are some strategies that can help.

- Start with a constraint map. Document each station’s sustainable rate, common stop reasons, and typical recovery time. Validate with observation, because recurring workarounds often do not appear in logs.

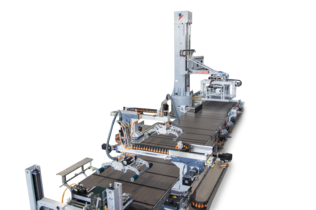

- Stabilize infeed and presentation. Better guides, controlled merges, and metering can raise throughput by improving pick reliability and reducing micro-stops. If case presentation is inconsistent, speeding up a robot rarely increases shipped output.

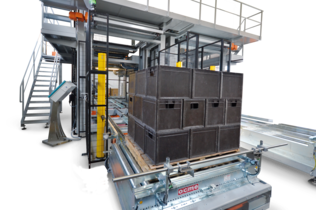

- Use buffering to decouple processes. Accumulation protects output from routine short pauses, especially before inspection gates, ahead of palletizers, and upstream of wrapper material changes. Size buffers based on the longest routine interruption you want to absorb.

- Design recovery paths on purpose. Provide clear jam access, simple reset sequences, and diagnostics that pinpoint the specific condition. In palletizing automation, controlled restart positions and a safe, well-defined manual mode reduce restart time.

- Treat controls as throughput equipment. Sensor filtering, handshakes, and motion profiles can impose hidden ceilings. If a “ready” signal arrives late or a timing window is too tight, you lose cycles without a visible fault. Revisit controls tuning after you run the real product mix.

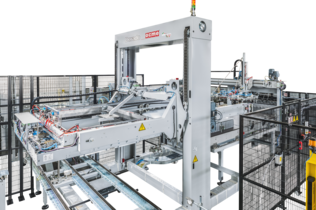

- Match the palletizing approach to rate and variability. Robot, conventional, and hybrid palletizers trade flexibility for raw rate in different ways. Select the approach that aligns with your sustainable rate, manages your SKU mix, and recovers quickly when input prices drift.

Real-World Examples in End-of-Line Packaging

Example 1: Rated Palletizer Output, Limited by Case Presentation

Your palletizing cell may be sized for the target rate, but skewed cases and inconsistent gaps force the robot to wait for a stable pick window. A metering conveyor and improved alignment can increase effective throughput without changing the robot or its program speed.

Example 2: Verification Pauses That Stop Upstream Equipment

A print-and-verify step may pause for reprint handling or scanner retries. With no accumulation ahead of it, the case packer repeatedly stops and restarts. Adding short accumulation and a clear reject path lets upstream equipment keep running while the exception is resolved.

Throughput is a system property. When you measure effective throughput, identify the real constraint, and shorten recovery time, you can increase shipped output without turning the line into a constant firefight.

Optimize Line Design Decisions Early With OCME USA

If you want to raise effective throughput without introducing new failure points, OCME USA can review your current performance, constraints, and production targets, and translate them into clear end-of-line design decisions. Our team understands where throughput is won and lost in end-of-line packaging automation, from case handling and accumulation to palletizing automation selection.